Both air conditioner fans run but no cool

The following instructions deal with lethal voltages. If you are not comfortable working near these voltages, call a professional.

If both the outdoor fan and the indoor fan are running, there is no problem with power.

At this point we need to determine if the compressor is running. After a thorough check for burned wiring, check the amperage draw through the contractor. If the compressor is running, the amperage draw should be anywhere from 8 to 30 amps. If the amp draw is 1 to 4, you are reading the amp draw of the fan motor and the compressor is not running.

At this point we need to determine if the compressor is running. After a thorough check for burned wiring, check the amperage draw through the contractor. If the compressor is running, the amperage draw should be anywhere from 8 to 30 amps. If the amp draw is 1 to 4, you are reading the amp draw of the fan motor and the compressor is not running.

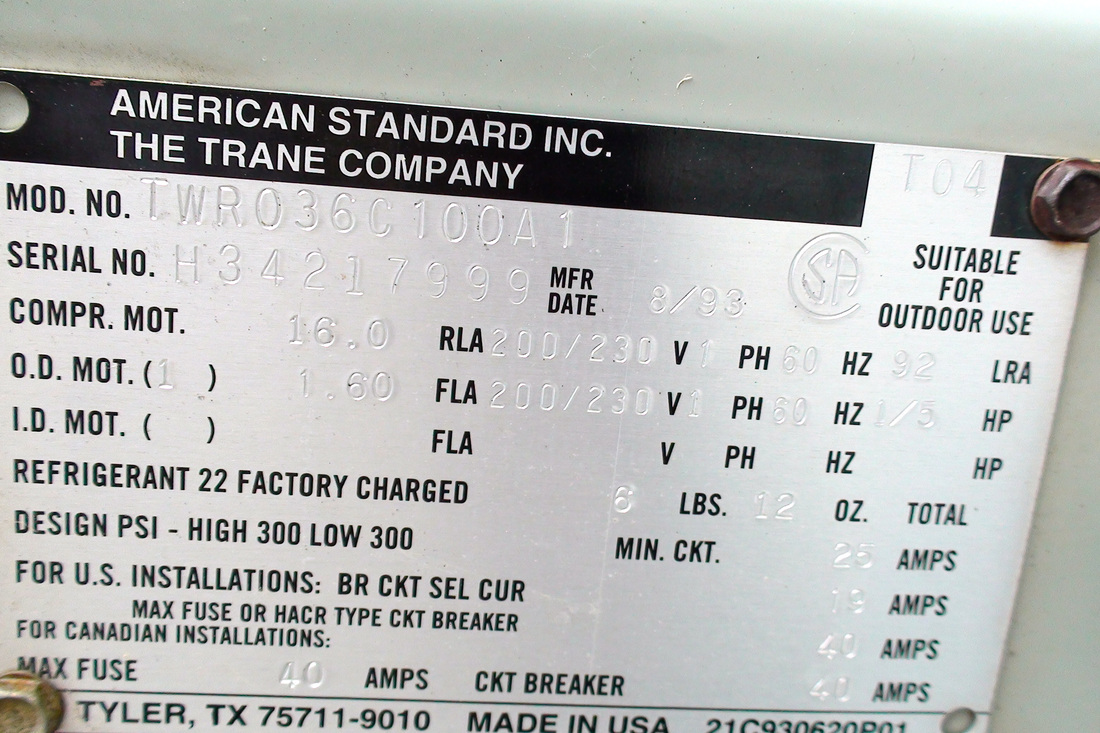

Below is a Model plate for an air conditioning outdoor unit.

Across from the title Compr. mot. you will see 16.0 RLA (Run load amps). The compressor should draw at or less than 16.0 amps.

Across from O. D. mot. note 1.6 amps. The outdoor fan should not draw more than 1.6 amps.

The power lead coming into the contactor carries both the od fan and the compressor amperage

If there is low amperage draw at the contactor

If only the fan motor amperage is read, the compressor is not running.

There are a number of reasons why a compressor is not running.

If the motor windings in the compressor are open, there will be no amperage draw.

To find out if the unit is out on overload, shut down the outdoor unit at the disconnect. If it is not excessively hot, it may reset in less than an hour.

One way to determine if the compressor is out on overload is to touch the compressor. Careful, it can be very hot!

If the compressor comes on after a time, and draws normal amperage (amperage draw can be found on the model plate).

There are a number of reasons why a compressor is not running.

If the motor windings in the compressor are open, there will be no amperage draw.

To find out if the unit is out on overload, shut down the outdoor unit at the disconnect. If it is not excessively hot, it may reset in less than an hour.

One way to determine if the compressor is out on overload is to touch the compressor. Careful, it can be very hot!

If the compressor comes on after a time, and draws normal amperage (amperage draw can be found on the model plate).

If the compressor is off on overload

There are several reasons for the compressor to be out on overload.

1. If the compressor has locked up mechanically it will not turn and the internal overload will have shut off power to the motor windings.

2. If the run capacitor has failed, the compressor will not start and the overload will shut off the compressor. On the left, are 2 capacitors. The one on the right is OK. The one on the left has failed as indicated by bulged top.

3. If the unit has been running low on refrigerant charge, the motor will overheat and the unit may be out on the internal overload.

4. If the voltage is below 10% of the rated voltage found on the model plate) for the unit it may not start.

5. The voltage may be over 10% of the rated voltage for the unit, it may then overdraw power and overheat.

6. The compressor valves may be broken. The compressor will draw excessively low amperage.

7. The expansion device may be plugged or not feeding refrigerant. The compressor gets no cooling and overheats.

1. If the compressor has locked up mechanically it will not turn and the internal overload will have shut off power to the motor windings.

2. If the run capacitor has failed, the compressor will not start and the overload will shut off the compressor. On the left, are 2 capacitors. The one on the right is OK. The one on the left has failed as indicated by bulged top.

3. If the unit has been running low on refrigerant charge, the motor will overheat and the unit may be out on the internal overload.

4. If the voltage is below 10% of the rated voltage found on the model plate) for the unit it may not start.

5. The voltage may be over 10% of the rated voltage for the unit, it may then overdraw power and overheat.

6. The compressor valves may be broken. The compressor will draw excessively low amperage.

7. The expansion device may be plugged or not feeding refrigerant. The compressor gets no cooling and overheats.

If the compressor runs and pumps but still there is no cool.

The most common reason for this is low or no refrigerant charge.

At this point you will need refrigeration tools and some knowledge to use them. Click here

The unit should be shut down. Install the manifold gauge set. If the pressure read is 0# or close to it the unit has no charge.

If so, the unit has a leak. click here

If, when the unit starts, the pressures stay the same, the unit has a mechanically failed compressor or a locked rotor compressor.

To determine which has happened, check amp draw. If amp draw is 1/2 or less than the model plate, and the pressures stay the same, the compressor has failed mechanically. If there is no amp draw, the compressor is out on overload, the capacitor has failed, (see above), the compressor has a locked rotor or has open windings. Below is a video on checking the windings of the compressor.

At this point you will need refrigeration tools and some knowledge to use them. Click here

The unit should be shut down. Install the manifold gauge set. If the pressure read is 0# or close to it the unit has no charge.

If so, the unit has a leak. click here

If, when the unit starts, the pressures stay the same, the unit has a mechanically failed compressor or a locked rotor compressor.

To determine which has happened, check amp draw. If amp draw is 1/2 or less than the model plate, and the pressures stay the same, the compressor has failed mechanically. If there is no amp draw, the compressor is out on overload, the capacitor has failed, (see above), the compressor has a locked rotor or has open windings. Below is a video on checking the windings of the compressor.