Air conditioning compressor problems

The following procedures require the use of a voltmeter and the ability to use it. Potential lethal voltages are used here. Know your limits.

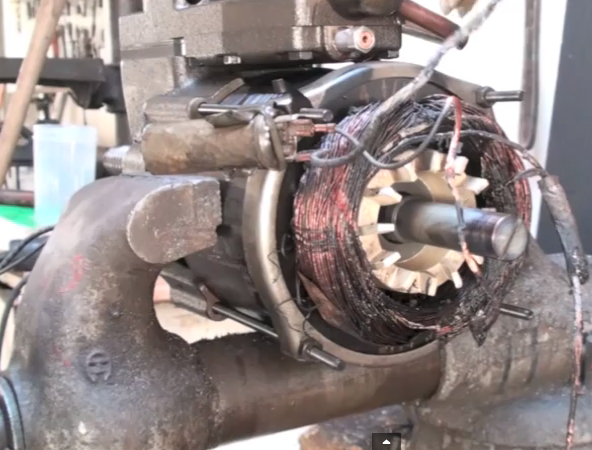

Compressor problems mostly involve electrical problems with the motor in the motor-compressor assembly.

The motor can fail in several ways.

1. The start winding can be open, in which case if power is available, the motor will not start, the run winding will overheat and the internal overload will shut down the power.

2. The run winding can be open, in which case if power is available, the motor will not start, the start winding may overheat and the internal overload will shut down the power. If the motor is a PSC, the motor will probably not overheat but just won't start.

3. Either winding can be shorted, in which case may not run or may run with excessive amperage which will probably open the circuit protection (circuit breaker or fuse).

4. Either winding may short to ground, Which will cause the circuit protection to open the circuit, sometimes even if the unit is not calling for heat.

5. The internal overload may fail open. In which case, no power will pass through so no amp draw will be seen. (If power is available at the compressor terminals, and no amp draw is shown, the internal overload may be open due to overheat, the unit must be cooled for the overload to reset.) This may take up to 24 hours.

If the overload does not reset, the compressor must be replaced.

Below is a video on internal overloads.

The motor can fail in several ways.

1. The start winding can be open, in which case if power is available, the motor will not start, the run winding will overheat and the internal overload will shut down the power.

2. The run winding can be open, in which case if power is available, the motor will not start, the start winding may overheat and the internal overload will shut down the power. If the motor is a PSC, the motor will probably not overheat but just won't start.

3. Either winding can be shorted, in which case may not run or may run with excessive amperage which will probably open the circuit protection (circuit breaker or fuse).

4. Either winding may short to ground, Which will cause the circuit protection to open the circuit, sometimes even if the unit is not calling for heat.

5. The internal overload may fail open. In which case, no power will pass through so no amp draw will be seen. (If power is available at the compressor terminals, and no amp draw is shown, the internal overload may be open due to overheat, the unit must be cooled for the overload to reset.) This may take up to 24 hours.

If the overload does not reset, the compressor must be replaced.

Below is a video on internal overloads.

Below and in the next video we are we are using an insulation tester to check the condition of the windings of the compressor.

This tool uses high voltage to probe for weaknesses in winding insulation.

In most cases, the windings will be open or shorted to ground. The diagnosis then is quite easily done using an ohmmeter.

However, detecting a future failure may be done using the insulation tester.

This tool uses high voltage to probe for weaknesses in winding insulation.

In most cases, the windings will be open or shorted to ground. The diagnosis then is quite easily done using an ohmmeter.

However, detecting a future failure may be done using the insulation tester.

Determining the condition of the windings can be tested using an ohmmeter or an insulation tester.

Below is a video that demonstrates a test of the windings to determine if they are at risk of failure soon.

Below is a video that demonstrates a test of the windings to determine if they are at risk of failure soon.